We are making professional nanoscale functional materials for fabrics. To put these materials into fibers with highly functions, we have very important core technology like powder miniaturization, surface modification, homogeneous dispersion, multifunction to make good dispersible functional powder so it can produce spinning masterbatch. Uniformly dispersed masterbatch is the basis of making highly functional fiber. It is also a guarantee for false twist and fabric using process afterwards.

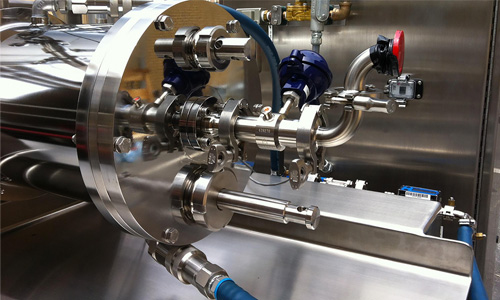

The functions of powder come from crystal structure, including mineral, plant, and high-temperature synthesis powder. The original powder is too rough to put into chemical fibers, so miniaturize powder becomes an important technical subject. Besides, the appearance of powder is also important. Rounding or passivating miniaturized powder is necessary to prevent transmissible elements being damaged during fiber procession. The main way to miniaturize powder is mechanical grinding. We have Jaw Crusher and Raymond Mill to coarse powder, and we imported precision grinding equipment to fine grind powders from abroad, which can grind powder up to 40 nanometers. By adding grinding medium and organic addictive, we can make miniaturized powder almost perfect round and better dispersion.

We setup large-scale powder granulation equipment to conduct particle size secondary processing to miniaturized powder, to make it flow well as functional powder material for spinnable masterbatch.

We mix the suitable interfacial agents for masterbatch and powder to form an active layer can function with solvent on powder's surface. So the miniaturized powder can disperse equally in the solvent. Appropriate surface modification exists in miniaturized powder pallet texture after drying. In the process of masterbatch manufacturing, it helps the powder in pallet texture decompose and disperse to melting chemical fiber materials, therefore the masterbatch will not raise spinning pressure in the spinning process. It can raise the yield rate in spinning. We use chemical methods to make surface modification on functional powder. The polymer on powder's surface makes powder flows easily in the masterbatch and fiber producing process. Under shear stress in spinning process, most of the powder can disperse on the surface of fiber to keep function.

Except chemical methods to modify the powder's nature, we also use high-speed homogenizer and bead mill. The blade and grinding medium have high shearing force, can break down powder pallet structure and disperse them into solvent equally, which produces the stable slurry. It improves the powder properties when spray drying, also provides high disperse slurry to wet spinning, raising the yield rate of spinning. Along with chemical modification and physical dispersion, we've developed a unique functional powder technology for spinning masterbatch. It ensures the powder's dispersion and function in the fibers so our customers can get high quality functional masterbatch and yarn.

Except chemical methods to modify the powder's nature, we also use high-speed homogenizer and bead mill. The blade and grinding medium have high shearing force, can break down powder pallet structure and disperse them into solvent equally, which produces the stable slurry. It improves the powder properties when spray drying, also provides high disperse slurry to wet spinning, raising the yield rate of spinning. Along with chemical modification and physical dispersion, we've developed a unique functional powder technology for spinning masterbatch. It ensures the powder's dispersion and function in the fibers so our customers can get high quality functional masterbatch and yarn.